Як правильно зробити монтаж опалення в приватному домен

In order for the heating system to work as efficiently as possible, it is important not only to choose a boiler suitable for power and other parameters, to correctly connect the required number of radiators, but also to take care of the wiring. It can be done in different ways. It depends on the efficiency of heating and cost savings. How to properly install heating in a private house?

Selecting a scheme

How to divide heating pipes? This can be done in different ways. When choosing the optimal wiring for a particular house, you need to familiarize yourself with their features.

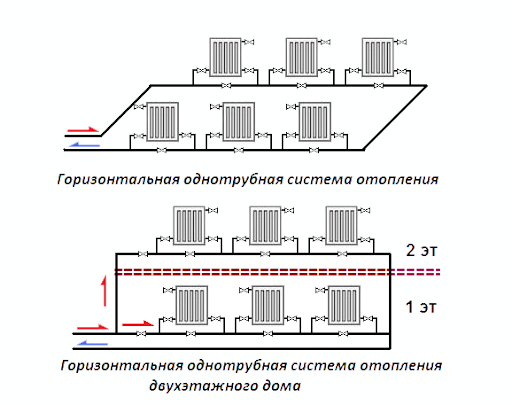

Single-pipe wiring

The scheme of this type of wiring is the most primitive and is currently used extremely rarely. During the installation of the heating system, one pipe is installed. It is from it that the closed circuit will consist. Different heaters will be connected to it alternately.

How to install heating correctly? The most common is the system where the lower wiring is carried out horizontally. So that the coolant can naturally circulate in a closed loop, the pipes are laid under a certain slope.

If the heating system is installed in a multi-storey building, it is necessary to take into account some of the nuances of the work. A shut-off device is attached to the branch pipe leading to the very first heater. It is necessary to shut off the water supply if necessary and to form a pressure that will allow the coolant to naturally move to the upper floors of the building.

If you install a system with a vertical type of wiring, all risers will be placed vertically to each other. For such a system, pipes with a larger diameter are selected.

The main advantage of the single-pipe type of connection with bottom wiring is the ability to achieve high-quality natural water circulation without the need to install a pump.

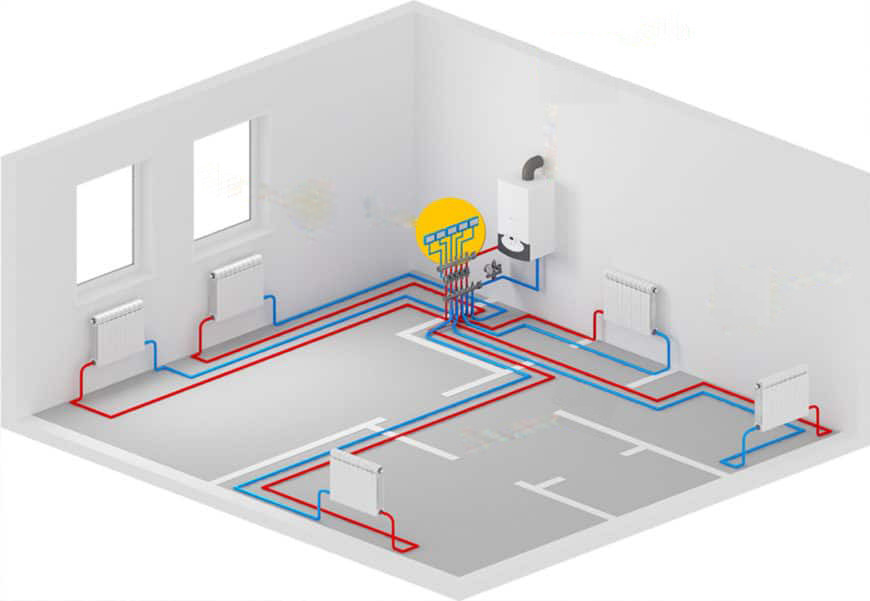

Other positive aspects of this wiring include: To eliminate this problem, it is enough to properly install heating in the house: This system is recognized as the most effective. It provides for the individual use of each heater in the system and connection to the collector group through direct and return pipelines. If the heating system is installed correctly, there is no cooling of the liquid in it. The disadvantage of collector wiring is considered to be high labor intensity and significant financial costs.

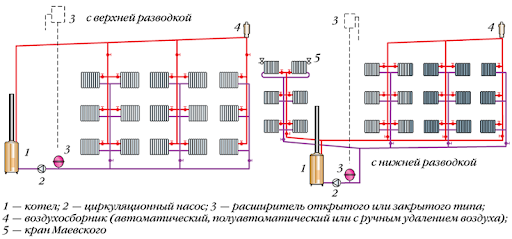

The installation scheme for a vertical with bottom wiring is as follows: In a vertical system, where the coolant is supplied from above, water goes to the heating devices through the supply pipe. It moves back through the return pipes. To avoid air accumulation inside the system, an expansion tank is installed.

The disadvantages of steel pipes are called: The advantage of wiring using copper pipes is: In order for the heating system to function efficiently, it is better to entrust the installation work to specialists. This will help to avoid mistakes that can lead to additional costs.The opportunity to save money. This is due to the fact that less materials and pipes are required.

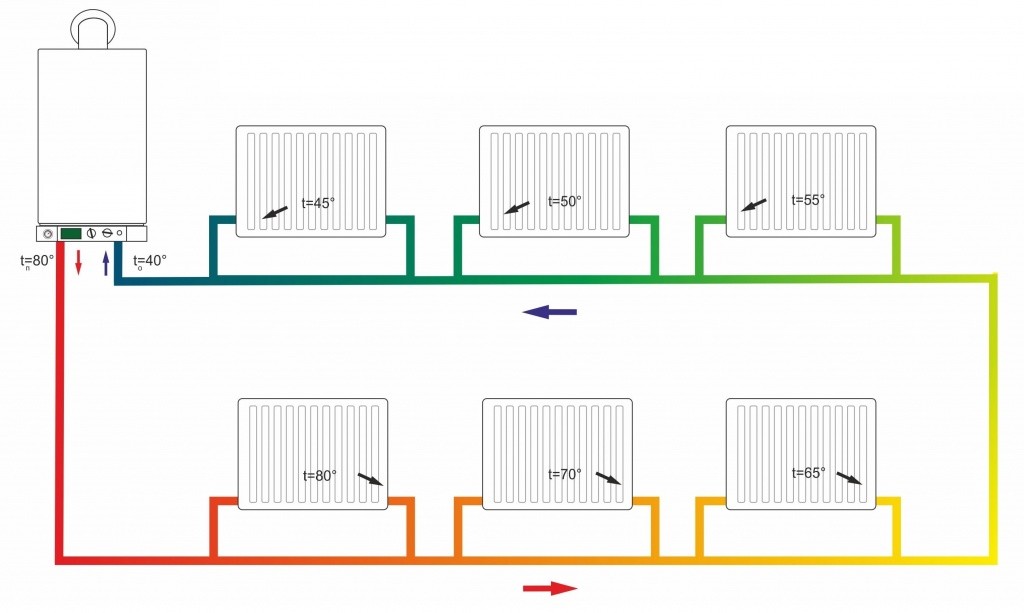

At the same time, it is worth considering the main disadvantage of such a heating system. It lies in the fact that the further the heater is from the boiler, the less it will heat up. This is due to heat loss at the entire stage of water movement in the system.

increase the number of sections of heating devices that are located farthest from the boiler;

As practice shows, such a wiring system will be effective in a room with an area of no more than 100 m2.

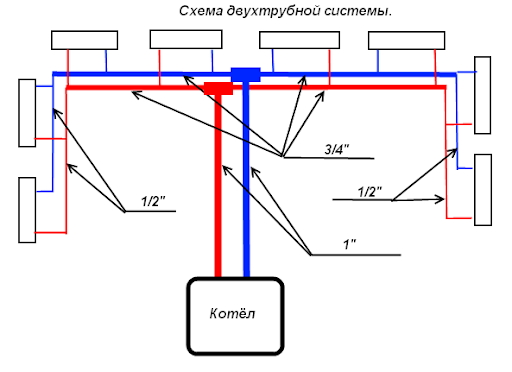

Two-pipe wiring

Heaters are connected to two pipes at the same time. One of them is supply, the other is return. This leads to the fact that more material is required for the installation of the heating system, and therefore increases financial costs. However, this scheme has its advantages. This is the ability to adjust the temperature on each radiator separately.

Collector wiring

Vertical schemes

On the lower floor, pipes are installed. The beginning of the pipeline is the boiler.

When choosing this wiring option, it is important to consider how the air will be regularly removed from the system.

Horizontal diagram

This type of wiring is the most popular. It is performed according to one of the schemes:Dead-end option. This does not require the use of many pipes, which saves on material. At the same time, the contour in such a system is very large. Because of this, there may be difficulties with adjusting the system.

When choosing a suitable wiring diagram, it is necessary to take into account the area of the room and the materials required for installation work.

Types of pipes for heating

Pipes can be made of metal (copper, stainless steel, galvanized and other types of steel), metal-plastic or polypropylene. Each material has its own characteristics that must be taken into account when deciding to carry out heating in a house.

Steel pipes

Steel can be ordinary or stainless. The advantage of this material is increased strength and thermal conductivity, a long service life and a minimum coefficient of thermal expansion.

a significant specific gravity, which makes the installation process more laborious;

Copper pipesPipes made of this metal can be annealed and unannealed. Their difference lies in the fact that the unannealed ones are able to withstand heavy loads, but their flexibility is insignificant. After annealing, which involves heating the material to high temperatures and then cooling it rapidly, copper becomes more elastic and able to withstand temperature fluctuations. At the same time, the strength of the metal decreases.

insignificant specific gravity (when comparing copper with steel);

However, when choosing copper pipes, it must be remembered that this metal is capable of reacting with aluminum. Therefore, it is forbidden to use them together in one system. Other disadvantages of the material are the high cost of pipes and fittings, as well as increased sensitivity to the coolant (even small solid fractions can damage the pipe walls due to the softness of copper).

Polypropylene pipes

The material has many advantages:small specific gravity, which makes wiring installation simple;

The disadvantages are as follows:

In case of poorly performed installation of polypropylene pipes, the tightness of the system may be compromised. Therefore, it is not recommended to use them in places where there are many joints, or to lay them in a hidden way.

Metal-plastic pipes

The complexity of laying metal-plastic pipes is minimal, so everyone can handle the work. Fittings are used for connection. The main advantage of this material is the absence of any deposits on the walls. But when choosing metal-plastic, it is worth remembering that system leaks are possible.