Які труби краще для опалення приватного будинку

In order for the house to always be warm and cozy, you need to know how to properly install heating in a private house. To do this, it is important to choose high-quality pipes that will guarantee the stable operation of the heating system.

Pipes in the heating system play an important role. They are necessary for the circulation of coolant in the system. The building materials market offers a huge selection of pipes. They differ in diameter, material of manufacture, price, etc. At the same time, each option has its own characteristics, positive and negative qualities. They must be taken into account in order to ensure reliable heating and indoor comfort.

The following requirements are imposed on pipes: When choosing the best pipe option, experts advise paying attention to the following points:

Pipes for heating: what should they be?

Durability. Even with long-term operation of the heating system, pipes must maintain their integrity. At the slightest damage to their walls or penetration of air inside, the corrosion process can begin. The pipe itself will begin to rust, and plaque will appear on its walls. If the pipe is severely damaged, leakage from the circuit will begin. And this can already lead to an emergency.

What to consider when choosing pipes?

The method of laying pipes. Wiring can be done in two ways: open and closed. With the open method, the pipes will not be hidden. When closed, they are placed in the wall, under drywall or other frame, under the floor.

The requirements for laying the heating system and the performance characteristics of the material from which the pipes are made are considered separately.Varieties of heating pipes

Before installing a heating system in a private house, you need to choose the material from which the pipes are made. They can be made from:

- steel (ordinary or stainless);

- polyethylene or polypropylene;

- copper;

- metal-plastic.

- Strength and reliability of the material. Steel has proven to be very resistant to sudden changes in temperature and pressure, as well as water hammer. This metal is also able to withstand significant mechanical loads.

- The minimum thermal expansion rate. This avoids the need to install compensators in the heating system.

- High thermal conductivity.

- Low cost. It is this indicator that often becomes the main one when choosing pipes.

- High thermal conductivity.

Stainless steel pipes for heating

Alloyed stainless steel is a more advanced material and is free from many of the disadvantages of steel materials. Stainless steel pipes have found their application in new and old buildings. Especially stainless steel pipes have become popular for plumbing and underfloor heating. This is made possible by the fact that the material bends perfectly.Other advantages of stainless steel include the following:

- Higher resistance to corrosion processes. Plaque and scale do not accumulate on the walls of such pipes. Therefore, they are characterized by high durability.

- Ability to withstand significant mechanical stress and water hammer.

- Minimum indicators of thermal expansion.

- High flexibility without reducing the pipe diameter. This quality is especially useful when installing the system in places where space is limited. Also, due to their flexibility, stainless steel pipes are suitable for creating systems with different configurations and a small number of connections. Therefore, pipes made of this metal are very often used to create underfloor heating.

- Ease of installation.

- High heat transfer performance.

- Wide range of applications.

- Ease of installation.

Copper pipes

Copper pipes for the heating system have been used for more than one hundred years, even though today materials have appeared on the market, the cost of which is several times lower. This is due to the advantages of copper. First of all, they are as follows:- Durability. Pipes and fittings made of copper can last more than 100 years without losing their characteristics.

- Resistance to corrosion and scale deposits on the walls, tightness and protection against air penetration. All this has become a guarantee that even after many years, the throughput of the copper pipe will not deteriorate.

- Resistance to temperature fluctuations. Copper pipes perfectly withstand operating temperatures in the range of -200 to +500 degrees. In addition, they are resistant to sudden changes in pressure in the circuit.

- High thermal conductivity.

- Attractive appearance.

- Resistance to temperature fluctuations. Copper pipes perfectly withstand operating temperatures in the range of -200 to +500 degrees. In addition, they are resistant to sudden changes in pressure in the circuit.

To extend the service life of copper pipes, it is important to refuse to combine them with unalloyed steel products, as they are very susceptible to corrosion.

Polyethylene pipes

This material is produced using a special technology, thanks to which it was possible to achieve its high strength. Polyethylene pipes have found their application not only in heating systems, but also in creating underfloor heating or hot water supply. The advantages of polyethylene pipes can be considered:

- resistance to corrosive processes;

Polypropylene pipes

Polypropylene — is a polymer whose advantages are as follows:- Durability. On average, polypropylene pipes can be used for more than 50 years.

- Resistance to corrosion processes. No deposits accumulate on the inner walls of polypropylene and their flow capacity is not impaired. Since the pipe is completely sealed, air penetration is completely excluded. If you choose a pipe reinforced with an aluminum film, the inner surface will be reliably protected from the effects of debris or metal elements that may be inside the system.

- Light weight.

- Strength and ability to withstand mechanical stress.

- Resistance to too high or low temperatures.

- Frost resistance. Since the material is capable of expanding, the pipe will not be damaged if the coolant freezes inside. After it thaws, it will take on its original shape again.

- The possibility of a tight connection through the use of welding or fittings.

- Ease of installation. To assemble the system, special fittings and a welding machine (soldering iron) are used.

- Minimum noise level.

- Safety for humans and the environment.

- Affordable cost.

- Light weight.

- the need to use compensators due to high linear expansion;

Metal-plastic pipes

This material has an optimal ratio of quality and cost. Metal-plastic consists of several layers. The outside and inside are plastic. Between them is aluminum foil. The advantages of metal-plastic are:- resistance to corrosive processes;

- insignificant resistance to open fire and mechanical stress;

- minimal resistance to ultraviolet radiation;

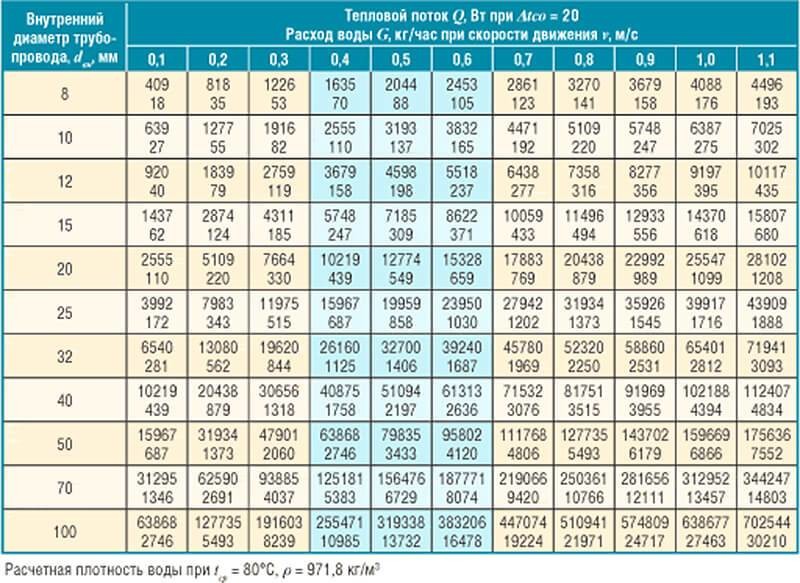

Selection of pipe diameter

Deciding on the material from which the pipes are made, it remains to choose the right diameter. To do this, take into account the area of the room and the speed of movement of the coolant inside the circuit.Pipes of too large a diameter will be ineffective, because the speed of movement of the coolant in them will be insignificant, which means that the room will not be able to warm up sufficiently.

A pipe of too small a diameter is also not suitable, since the movement of water in it is accompanied by an increased noise level, and the system operation period will be reduced. The optimal diameter is calculated based on the heat output. For example, with a ceiling height of 3 meters in a room, 100 watts of energy is required for each square meter of space for heating. Additionally, a 20% margin is added. The resulting value is compared with a table that determines the optimal pipe diameter.

The choice of pipes for the installation of the heating system must be approached as responsibly as possible. This is due to the fact that even a small mistake may require complete dismantling and new installation of the system.