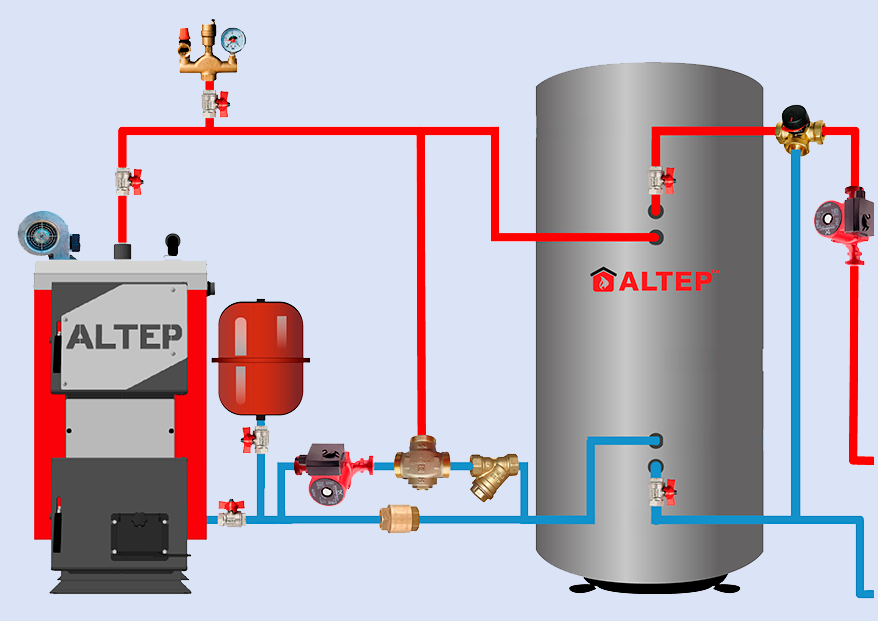

Схема підключення буферної ємності до твердопаливного котла

Heating is always a hot topic, given the rise in tariffs. And recently, more and more often consumers of solid fuel equipment are encouraged to install a buffer tank in the system. This is really a huge advantage in saving money and time for the maintenance of solid fuel equipment. It is ideal to connect the buffer tank to the boiler at the same time when installing a solid fuel boiler.

A solid fuel boiler and a heat accumulator in tandem have their advantages in heating. You can have the simplest solid fuel boiler, without modern modifications, but with the use of a tank in the system, its operation will give a head start to any long-burning boiler, or at least will not be inferior in the comfort of maintenance and will correctly consume heat, reduce the number of approaches to the furnace chamber and fuel costs.

The main reasons for connecting a buffer tank:

- The need to save costs;