Схема об'вязки твердопаливвного котла

Binding of the boiler is the combination of the heating system, all units, circuits and elements into a single complex in accordance with the rules and regulations for the operation of equipment. This allows you to make the operation of the boiler safe and efficient.

To determine how to properly make the boiler strapping, experts advise you to familiarize yourself with the possible methods in advance. They may differ depending on the type of boiler and the option for organizing the flow.

The heating scheme can be open or closed. As for the circulation of the energy carrier, it is divided into gravitational and forced.

The open version involves the use of an expansion tank without a lid. Its main tasks are as follows: Before the heating boiler is strapped, it is schematically depicted: When choosing the method by which you plan to carry out the piping of the boiler, it is important to take into account the presence of a heat accumulator. In cases where the use of a buffer tank is not provided, the heating system includes large and small circles of the heating system. The installation of a small circle is carried out according to the following algorithm:How to make a boiler strapping

In the closed version, there is no communication with the atmosphere, and the circuit is under pressure. For such a design, overheating is very dangerous, as it can damage the pipeline or devices. To protect the circuit from a possible hydraulic shock, the system has an expansion tank equipped with a membrane.

The first and most important point is the choice of a boiler. When purchasing equipment, consider:External volume;

Based on these data, a heat engineering calculation is made. The term and efficiency of the system operation, prevention of its overheating depends on how correctly the piping scheme of the heating boiler is drawn up.

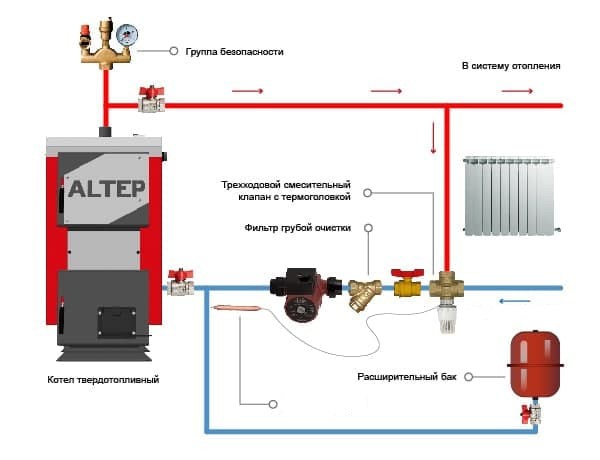

Correct strapping of a solid fuel boiler

The scheme of strapping a solid fuel boiler is as follows.

After the solid fuel boiler, a safety group is installed.

This scheme works as follows:

- When a solid fuel boiler is put into operation, the coolant moves in a small circle. To prevent cold water from entering the heat exchanger, a travel valve is used. If a temperature drop is allowed, condensation will appear in the boiler, which can damage the heat exchanger.

- After the coolant is heated to a temperature of 60 degrees, the three-way valve opens and a large circle comes into operation.

- At the same time, the small circle works as a mixing unit, protecting the coolant from boiling and correcting the temperature difference between the supply and return flow.

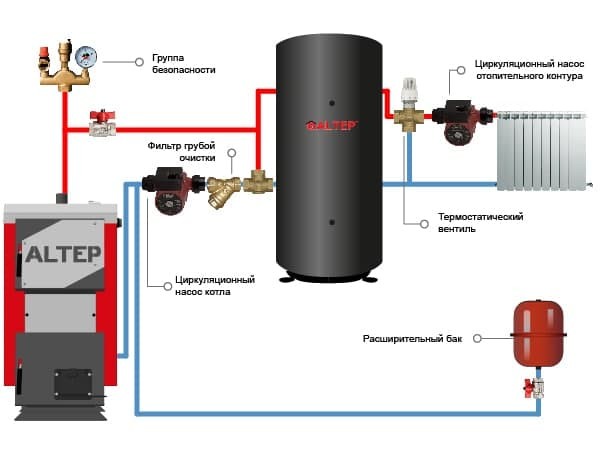

A thermal storage device, or buffer capacity, helps:

- save up to 50% on fuel;

- protect the boiler from overheating in case of an emergency;

- reduces the number of fuel loads, making the use of a solid fuel boiler more convenient;

- stabilize the boiler operation in one mode;

- store heat during the off-season; ensure system controllability.

The simplest and most affordable scheme for strapping a solid fuel boiler with a buffer tank can be considered the following:

- boiler;

- pipeline;

- heat accumulator;

- circulation pump.

- When installing a heat accumulator, you cannot use a welding type connection;

- installation is carried out using couplings equipped with a flange or thread;

- the pipeline must be equipped with shut-off valves;

- Temperature sensors must be installed on all circuits;

- a drainage valve must be present in the system;

- coarse filters must be present at all inlets;

- an automatic air vent is important;

- to avoid freezing of the coolant in winter, its installation is carried out exclusively in a warm room;

- it is important to have free access to all circuits.

- a three-way mixing valve;

- connected circulation pump.