Який димохід краще для будинку та твердопаливного котла?

Types of chimneys

The chimney is an integral part of the heating system, organized on the basis of a solid fuel boiler. The stability and efficiency of the boiler depends on the chimney, or rather on its design and quality of execution.There are several types of chimneys that differ in materials and design. Each type of chimney has its pros and cons. Let's take a closer look at what types of chimneys are available and what are the pros and cons of each type.

- brick or masonry chimney

- masonry chimney

- metal chimney

This type of chimney is very common due to the traditional use of bricks in the construction of residential chimneys. As a rule, such chimneys are common in already constructed buildings and are their architectural part.

Since brick and stone have such physical properties as a high level of heat capacity and thermal conductivity, the operation of chimneys made of this material has the following nuances:

- When starting a boiler with a cold brick chimney, a very weak draft effect may be observed, which will manifest itself in a smoky boiler room. The effect of weak draft will be present until the chimney is completely warmed up.

- turning over the draft;

- smoke in the boiler room;

- the formation of a large amount of condensation in the pipe and, as a result, the rapid contamination of the chimney with soot and resins.

- ease of installation

- ease of cleaning

- minimal condensation formation

- aesthetic appearance

- weakening of traction and, as a result, smoke in the boiler room; swirling of smoke around the pipe, which entails a deterioration in the appearance of the chimney due to pollution;In order to avoid the above troubles, it should be remembered that the distance from the edge of the pipe to the inner surface of the fungus should be no less than the diameter of the chimney.

- a soot collector with a door, inspection hatches in the horizontal parts of the chimney.

Metal chimneys

Metal chimneys are the most common type of chimney. Usually, they are made of round or rarely rectangular pipes. Both ordinary and stainless steel can be used as a material. Chimneys made of ordinary steel are significantly inferior to stainless steel chimneys in terms of durability, especially if the construction lacks thermal insulation. However, on the other hand, a stainless steel chimney is much more expensive.

Important! It is not recommended to make a chimney from galvanized steel. Such chimneys are extremely short-lived, literally for one or two seasons.

In any case, it is recommended to insulate any metal chimney along its entire length. Only a thermally insulated chimney allows you to get rid of such unpleasant phenomena as: Today, the best type of chimney is the so-called sandwich chimney. Structurally, such a chimney consists of two pipes - an inner one made of stainless steel and an outer one made of galvanized or stainless steel. Between the inner and outer pipe is a heat-insulating layer of basalt fiber or other heat-insulating material. Thanks to the presence of a thermal insulation layer, such chimneys warm up quickly and retain the necessary draft and, of course, minimize the formation of condensation inside.

Which chimney is better for a solid fuel boiler?

The advantages of a sandwich chimney are:

- durability

Important! When choosing a chimney, you should take into account the technical requirements of the manufacturer of the solid fuel boiler regarding the cross-sectional area and height of the chimney. This information is contained in the operating instructions for the solid fuel boiler. At the same time, such a parameter as the minimum chimney height at each specific facility may differ from the one recommended by the manufacturer of the solid fuel boiler. The difference can be both upward and downward, and this directly depends on the height of the building itself, as well as on the terrain of the surrounding area and the presence of tall objects on it.

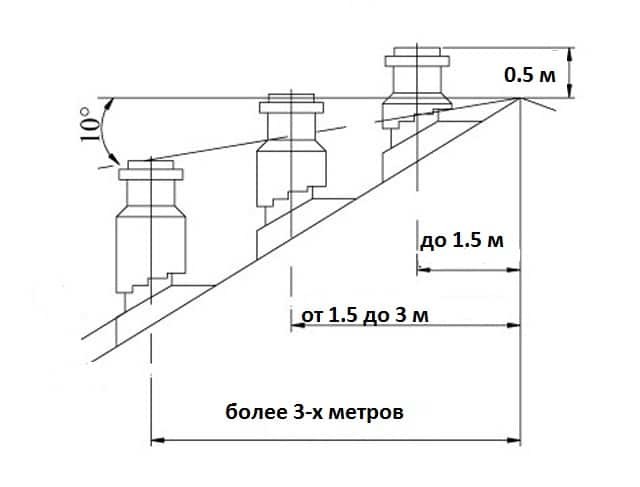

According to the above diagram, the upper end of the chimney as it moves away from the ridge of the building should fall into the sector of 10 degrees relative to the roof ridge.

The height of the chimney for a solid fuel boiler

When installing a chimney, the following rule must be observed - the chimney must always be at least half a meter higher than the highest point of the building! However, with sufficient distance from the highest point of the building, the chimney can be made lower. The relationship between the height of the chimney and the distance to the highest point of the house can be illustrated by the following figure.

Installing fungi and weathercocks on the chimney

Fungi on the chimney are installed to protect the chimney from precipitation. The installation of a chimney fungus should be approached responsibly. The fact is that if the distance between the edge of the pipe and the inner plane of the fungus is too small, the following unpleasant phenomena may occur:

Lately, the installation of such an element as a weather vane on the edge of the chimney has become popular. This element of the chimney system allows you to direct smoke strictly in the direction of the wind. However, sometimes this element may become jammed due to icing, as a result of which, when the wind direction changes to the opposite, the traction disappears. Therefore, due to this problem, installing a weather vane on the chimney is not recommended.

Cleaning and maintenance of the chimney

Important! Cleaning the chimney is an inevitable and extremely necessary measure, since a dirty chimney is the cause of the loss of traction and all the negative aspects associated with it.Already at the design stage of the chimney, the organization of such elements as:

Cleaning can be carried out as the chimney becomes dirty, but at least once during the heating season.

Important! A properly designed, installed and timely maintained chimney is the key to the stability and efficiency of a solid fuel boiler.