How does automation for a solid fuel boiler work?

Modern life is impossible to imagine without the automation of various processes. Automation is a set of devices that ensure the normal and continuous operation of various devices and apparatus. Automated systems must include devices that will monitor the safety of their operation. This is especially important for heating systems with a solid fuel boiler.

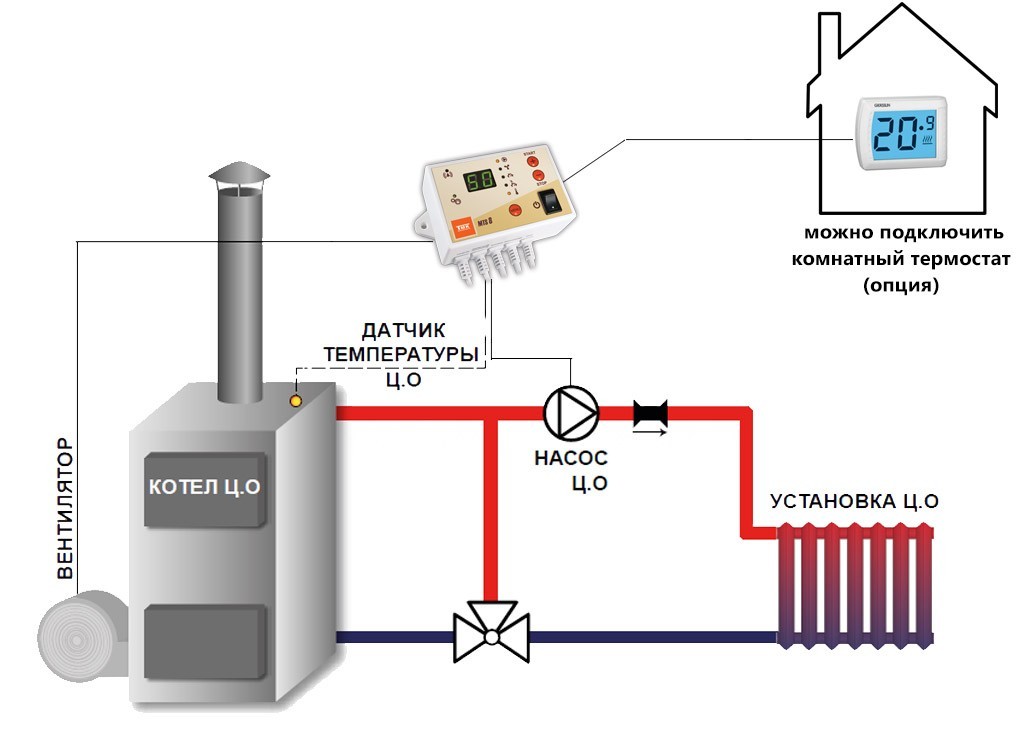

The principle of operation of the automation of a solid fuel boiler

Automatic systems for solid fuel boilers are able to exercise full control over the operation of equipment, heat generation and the process of heating the room. At the same time, a person can only set the optimal temperature level and load fuel in a timely manner.Automation is able to control the combustion process in the furnace.

Automation for a solid fuel boiler may include:Control unit, or microprocessor. This device can be called the brain center of automation, since its task is to analyze all the data received by the device from the smoke exhauster, fan, and other elements of the system. The temperature and comfort in the house depends on the microprocessor.

The use of automation for a solid fuel boiler allows you to maintain the temperature set by the user at the same level. Other advantages also include the possibility of using any solid fuel and improving the process of its combustion.

The principle of the device is to control air flow. The algorithm of its action is as follows:How does the thrust regulator work?

During the combustion of fuel, the coolant is heated and expanded, which acts on the actuator, compressing the spring.