Підключення триходового клапана до системи опалення

In any heating system organized on the basis of a solid fuel boiler, so-called mixing valves must be present. Their type and number in the scheme may vary in each specific heating system. We will talk about how a three-way system valve works, what are the main common types of mixing valves, and their practical purpose in this article.

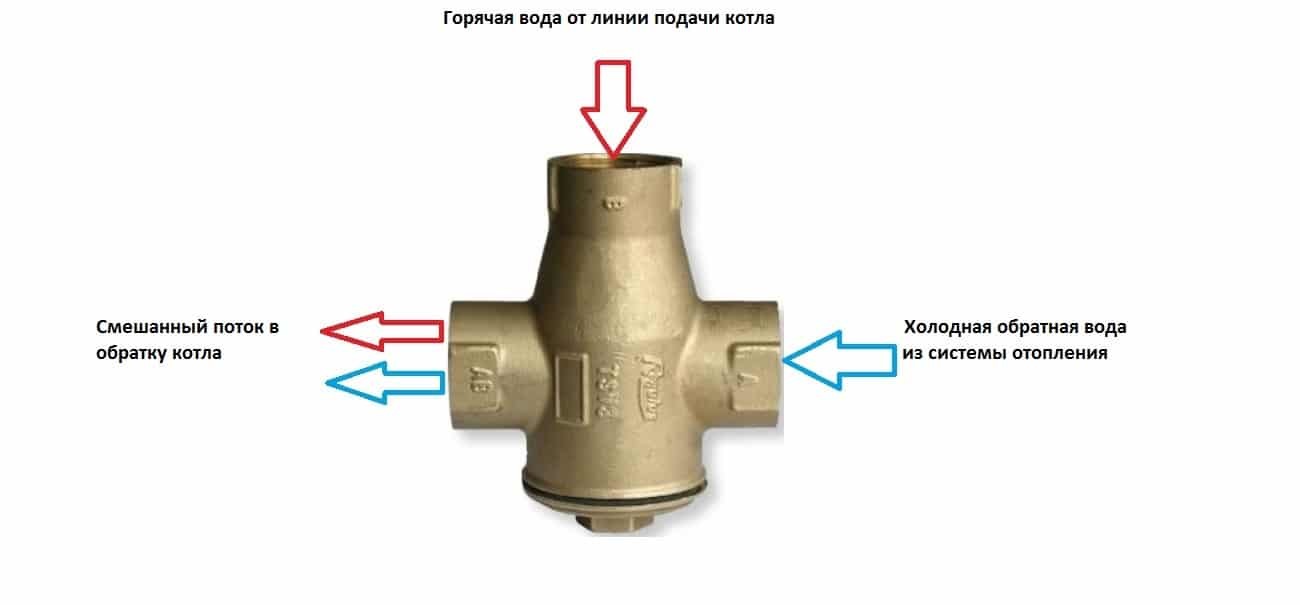

Three-way thermostatic mixing valve

Why do you need a three-way system valve in a solid fuel boiler - a three-way thermostatic mixing valve is designed to protect a solid fuel boiler from condensation. Therefore, this device is also often called an anti-condensation valve.The device of this valve has a thermosensitive element, which, when heated, drives a spring-loaded rod, which in turn opens or closes one of the valve channels.

This valve works as follows

Hot water flows to the inlet of valve B through the bypass channel, while water flows through channel A from the return of the heating system. The valve mixes these two streams, resulting in a mixed stream with a given temperature on the AB channel. Moreover, the temperature of this mixed flow depends on the temperature schedule for opening the valve for each specific thermostat.There are three-way thermostatic mixing valves on sale with different opening temperatures, for example, 45°C, 55°C, 61°C, 72°C, etc. To protect a solid fuel boiler from condensation, valves with an opening temperature of at least 55 °C are usually used. The choice of the thermostat by the opening temperature depends on the temperature regime at which the solid fuel boiler is supposed to be operated. For example, a solid fuel boiler will be operated at a coolant temperature of 60 °C. Then, under this condition, it is necessary to install a thermostatic mixing valve with an opening temperature of 55 °C.

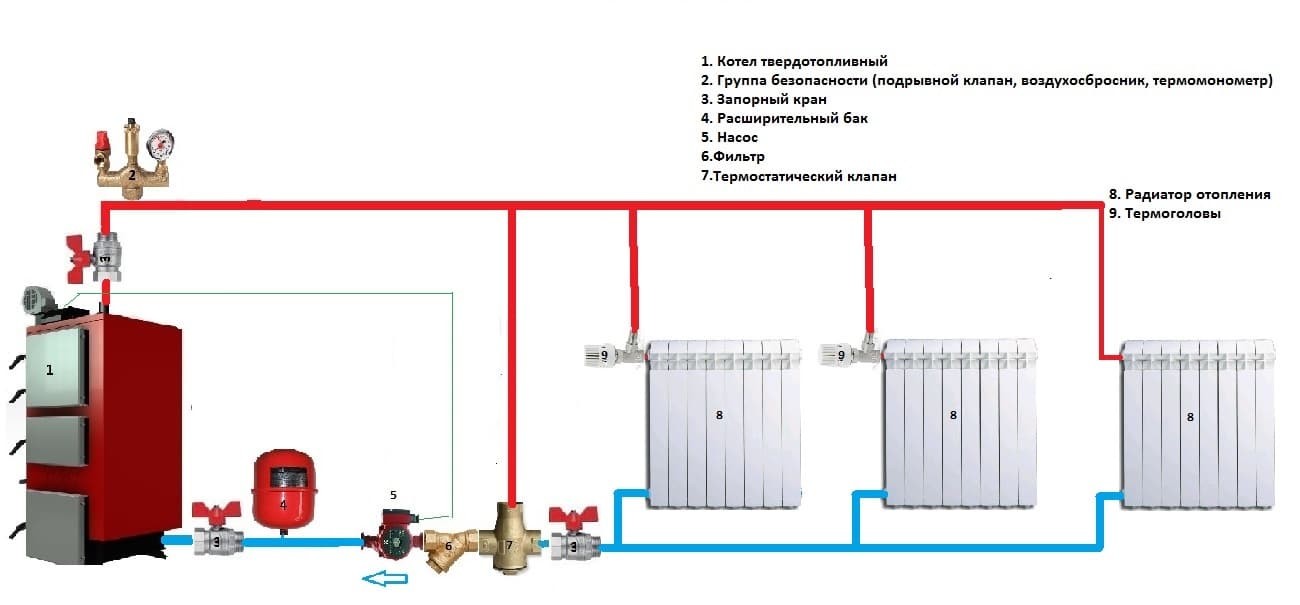

Wiring diagram of a thermostatic mixing valve

A three-way thermostatic mixing valve is a relatively inexpensive device that allows you to reliably protect the solid fuel boiler from the condensation effect, and accordingly, significantly reduces the formation of various deposits on the walls of the boiler.

In addition to the above beneficial effects, it is worth noting that the thermostatic valve directly affects the efficiency of the boiler, as well as its service life.

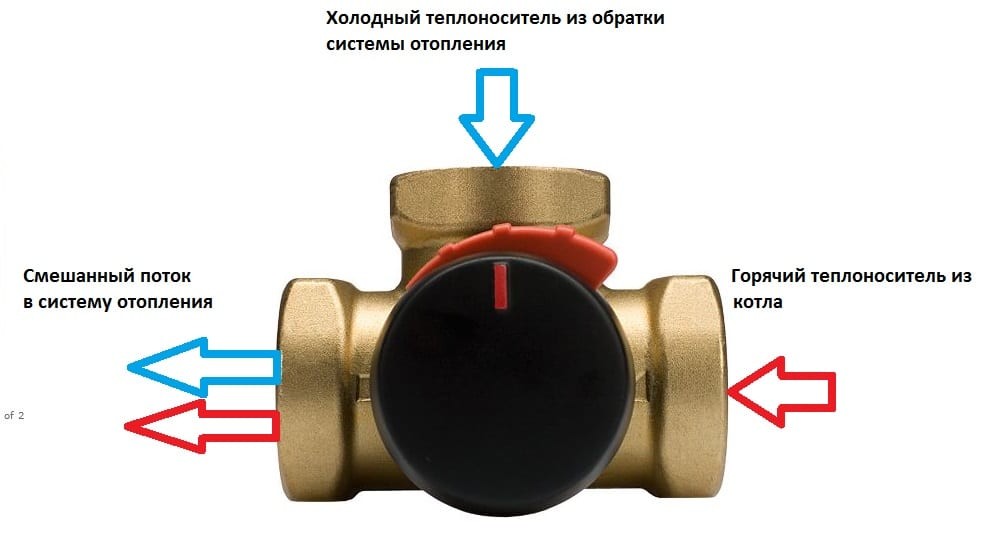

Three way mixer valve

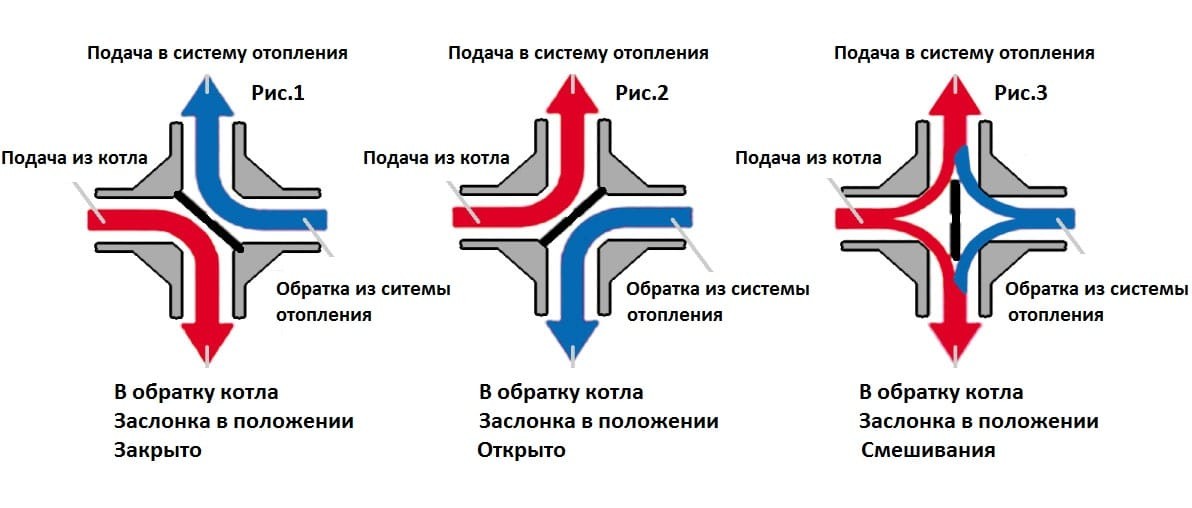

A three-way mixer valve is a device with three channels, between which a rotary valve is located, when it is turned in one direction or another, the flows are mixed in the valve. Unlike a stroke thermostatic valve, in a three-way mixing valve, the temperature regime of the mixed flow is not static, but can vary over a wide range The figure below shows the valve's operating scheme. In practice, the valve's operation can be described as follows. Let's say that one of the valve channels receives a hot heat transfer medium from the boiler or distribution manifold, while another valve channel receives a colder heat transfer medium from the heating system return. On the third channel of the valve, we can get a mixed flow of coolant with a different temperature regime from the other two flows.

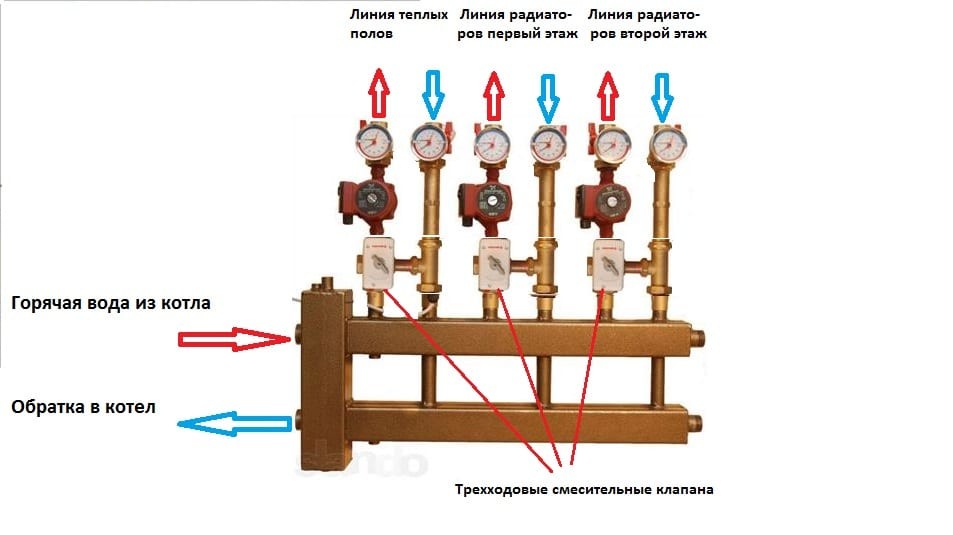

The three-way mixing valve is used in those parts of the hydraulic circuit of the heating system where it is necessary to obtain a flow of coolant with a variable temperature regime. Consider how to use this type of valve using the diagram below.

The diagram shows a distribution manifold for three separate heating lines. In our case, the heating lines are a system of underfloor heating, first floor radiators and second floor radiators. Suppose that a coolant with a temperature of seventy degrees enters the collector from the boiler. Such a temperature is not terrible for radiators, but underfloor heating with such a temperature should not be allowed. This is where the three-way mixing valve comes in. By mixing cold coolant from the return flow into the supply, the valve allows you to create the temperature regime we need at the supply. Moreover, you can create your own temperature regime on all three lines independently of each other. On the radiator line, a three-way mixing valve is also very useful, as it allows you to reduce the temperature on the radiators, for example, when the room has already warmed up and the coolant in the radiators is not needed. The diagram shows three-way mixing valves equipped with servo drives, which allow the valves to be controlled automatically. The servo drive allows you to very accurately maintain the set temperature in the room, thanks to clear feedback from the thermostatic automation.

Four-way mixing valve

A four-way mixing valve is a device with 4 channels and a rotary valve between the channels. Unlike three-way valves, in a four-way valve, flows can be mixed in two directions at once.

Diagram of the four-way mixing valve

Scheme of operation of the four-way mixing valve

The four-way valve works as follows. When the valve is completely closed (Fig. 1.) Mixing does not occur, and the hot coolant goes in a small circle, without entering the heating system, returns to the boiler. When the valve is turned, the coolant flows are mixed in two directions: one mixed flow goes to the heating system, and the other mixed flow goes to the boiler return. By slightly turning the damper to the left or right, you can change the temperature in the heating system and the boiler return. For example, a coolant with a temperature of seventy degrees comes out of the boiler, and we need fifty degrees in the heating system. By turning the valve flap, we dilute the 70-degree coolant coming from the boiler supply with a colder coolant coming from the heating system return.

With the damper fully open, no mixing of the flows occurs and the coolant goes in a large circle directly into the heating system. It is worth noting that there are models of four-way valves in which the positions of fully closed and fully open do not exist, that is, mixing of flows is always present, albeit to a minimum extent.

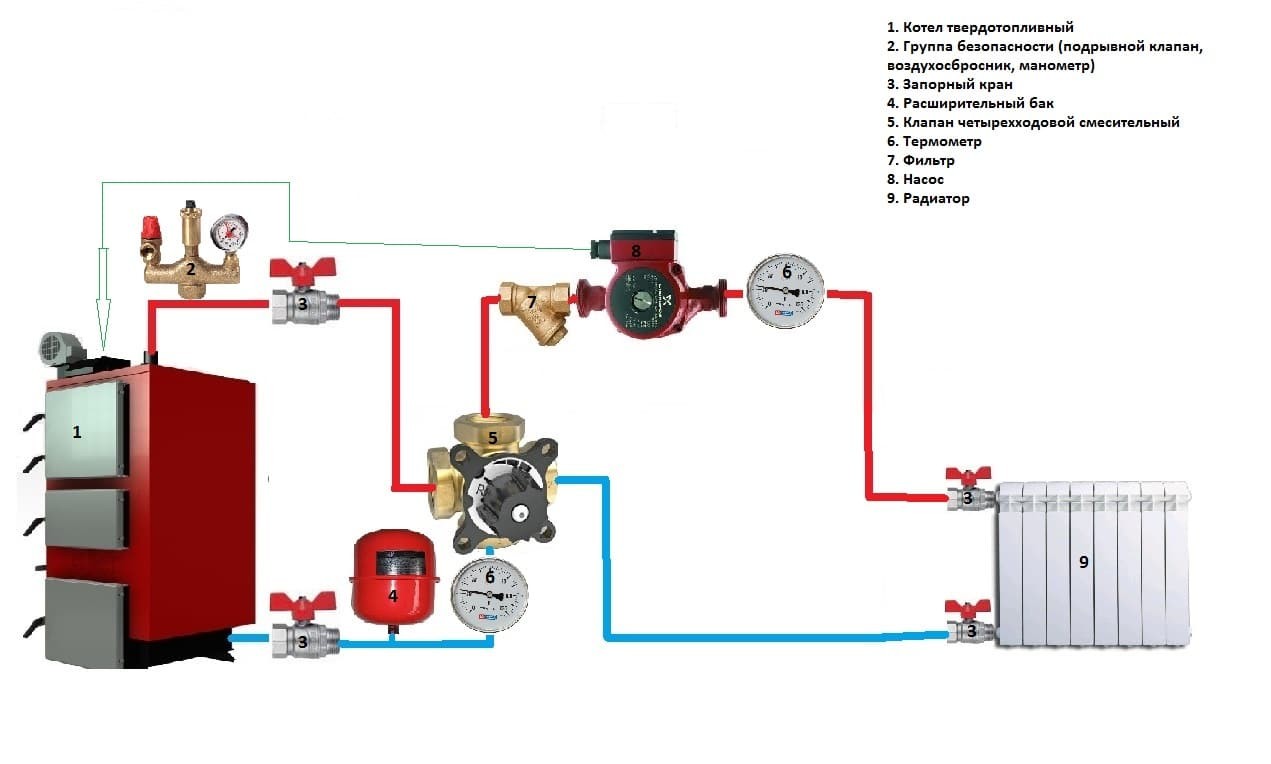

Classic scheme of using a four-way mixing valve

The four-way mixing valve can be controlled both manually and automatically using a servo drive. The servo drive automatically turns the flap of the four-way valve in the desired direction according to signals received from a special control unit, which, in turn, is programmed to create the desired temperature flow in the heating system.

As practice shows, a four-way mixing valve is a very useful element of the heating system, which can significantly increase the comfort of operation of a solid fuel boiler. In fact, a four-way valve provides the following features:

.

- Maintaining the required temperature in the heated room, especially during the off-season and thaws;